1 reviews

•29 Colors

1 reviews

•29 Colors

Showing 1-24 of 71 Products

The highest quality rubber flooring comes from American manufacturers. When you stick with US rubber tiles and rolls from Greatmats, you can be certain that the manufacturer is using pure rubber products and is following precise manufacturing tolerances.

Rubber flooring is extremely durable, giving customers several years of performance, even in conditions where the flooring undergoes rough treatment and exists in harsh conditions.

Size and Shape Options

US rubber products for flooring are available in both rolls and interlocking tiles. Because of their weight and large size, rolls work well for those who have plenty of help and power equipment to move them. Interlocking tiles are smaller than rolls, so they’re easier to move around, but they take longer to install than rolls.

For rolls, Greatmats typically offers 4-foot widths with custom-cut lengths, usually with a minimum order of 15 linear feet. We sell a few of our rolls in precut sizes of 4 by 10 feet.

For tiles, the most common size we offer is 2 by 2 feet. Because of the jigsaw puzzle-style edges on these tiles, you will not quite receive a full 4 square feet of coverage per tile. If you need help determining how many 2x2 US rubber tiles to order to cover certain square footage, call our customer service team.

Multiple thickness options are available, although 3/8 inch is a popular choice. We also offer these tiles and rolls in 1/8, 1/4, and 1/2 inch options. Thicker rubber delivers better durability, but it’s also heavier and more expensive than thinner rubber.

Material Options

Rubber is a popular choice for many kinds of flooring installations, as it will provide long-lasting performance. Expect to receive at least a 5-year manufacturer warranty on these flooring products. Many customers report receiving a far longer useful lifespan.

Rubber works well for many different types of planned use cases as well, providing plenty of versatility and value.

For our US rubber rolls and tiles, the manufacturer primarily uses recycled rubber from tires. This is a safe use for recycled rubber. It is an eco-friendly option, as it keeps old tires out of landfills by giving them a new, useful life. Our floors can help customers achieve LEED points for their buildings as well.

Pattern and Texture Options

Rubber has a naturally tacky texture to it, which prevents slips when the flooring is wet. This makes rubber a smart selection for fitness centers or home gyms where athletes need to maintain a sure footing.

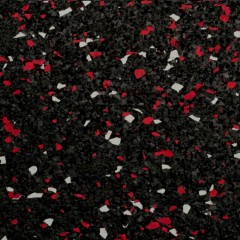

For our US rubber products, a black base color is the most common option. However, some products will have color flecks included in them. A 10 or 20 percent fleck is common against the black base. Color fleck options can include white, green, red, orange, gray, blue, and others.

Adding the color flecks usually occurs with EPDM (Ethylene Propylene Diene Monomer) chips. This is a synthetic type of rubber. The mix of recycled rubber tires and EPDM rubber does not affect the durability of the flooring in any way.

Common Use Options

Rubber is a great choice for flooring in areas where excessive sound is a problem. Rubber naturally absorbs noise and creates a more pleasant atmosphere for everyone using the space.

Gymnasiums and athletic facilities are the most common areas for installing this style of flooring. Rubber is especially popular in places where weightlifting occurs, as the rubber can withstand the weight of barbells and weight plates without showing damage. The rubber also protects the subfloor.

Some customers will place the rubber flooring in areas where quite a bit of dampness is possible. Commercial kitchens and dishwashing stations may install rubber floors to prevent the possibility of slips from wet flooring.

Installation Options

To install interlocking tiles like our Survivor Sport floors, simply line up the tabs on one tile with the slots on an adjacent tile and press the edges together. The manufacturer uses water jet cutting technology to make precise cuts, meaning the tabs and slots will fit tightly together without needing glue.

For rolls of rubber, simply place them in the room and unroll them like you would unroll carpeting.

For a permanent installation, you can glue the rubber to the subfloor. If you want to be able to remove the rubber flooring in the future, do not use glue. The weight of the rubber often holds it in place without needing adhesive.

Cleaning and Maintenance Requirements

US rubber is a popular choice for flooring because of how easy it is to clean. Start by sweeping or vacuuming the flooring to remove dry debris and dust. In areas with heavy traffic, remove debris daily to prevent anything from setting into the rubber and causing staining.

For more thorough cleaning, use a mop and a neutral pH cleaning solution. You can rinse the mats with clean water and a mop, if desired. Allow the rubber to air dry, or use a wet/dry vacuum to remove puddles after cleaning the floor.

$338 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$324 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$8821 /Roll You Save 19%$2.21/sqftShips Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$200 /sqft You Save 20%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$138 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$124 /sqft You Save 20%Ships Out in 7-10 Working Days SustainableShop$293 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$293 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop

$338 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$324 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$8821 /Roll You Save 19%$2.21/sqftShips Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$221 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$200 /sqft You Save 20%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$145 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$138 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$124 /sqft You Save 20%Ships Out in 7-10 Working Days SustainableShop$293 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop$293 /sqft You Save 19%Ships Out in 7-10 Working Days SustainableShop