Polypropylene Garage Floor Tiles for Fast Installation

Related Product: TurboTile Diamond Garage Floor Tile 5/8 Inch x 1x1 Ft.

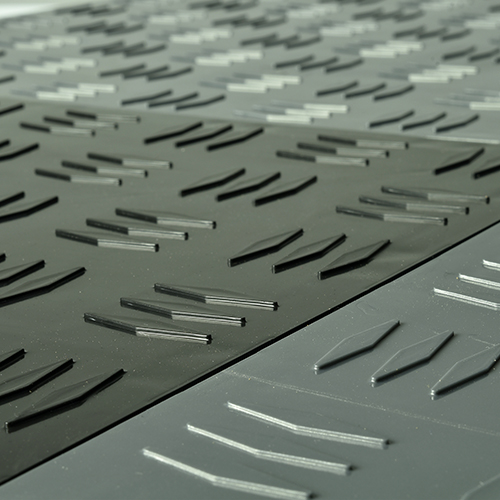

These tiles don’t sacrifice a sharp look to achieve the desired toughness, though. They’re available in multiple colors and with a tread texture pattern that adds to the aesthetics of the top of the layout, while providing traction.

Additionally, Greatmats’ polypropylene garage floor tiles use a raised base in the plastic, which uses pegs to lift the base a fraction of an inch off the floor. This encourages airflow underneath, which helps evaporate moisture in a wet garage.

Another benefit of these tiles is the hidden interlocking edge. Installation goes quickly, thanks to the tabs and loops on the edges. Installers can assemble and disassemble the tiles safely many times.

With the hidden interlocking system, once the installer completes the tile layout, all that will be visible are clean, straight lines between the tiles. This allows for mixing and matching of colors in the design.

Edges will need to either be cut to fit or covered with snap-together ramped borders.

Some of the most common use cases for polypropylene garage floor tiles include:

- Car showroom floors

- Motorcycle showrooms

- Automotive repair shops

- Trade shows

- Special events

- Basements

- Storage sheds

- Residential garages

What Is the Best Tile for a Garage Floor?

The Garage Floor Tile Diamond product is one of the best polypropylene garage floor tiles available. Not only is it able to withstand wear and tear from driving and parking large vehicles on it, but it also looks great.Color options available with these tiles include:

- Black

- Dark gray

Additionally, this tile has a raised triple diamond tread pattern printed across the top of the tile. This provides traction for those walking across it, which is especially helpful if the tiles become wet from moisture dripping off the vehicles.

The polypropylene plastic will not absorb water, making it ideal to use in areas that see frequent dampness. There are no concerns about mold and mildew -- or the associated odors -- forming with these tiles.

Each 1-by-1-foot tile measures 5/8 inch in thickness. To reduce a tripping hazard over the lip of the flooring installation, customers can choose a ramped border edge that connects to the interlocking edges on the tiles.

The manufacturer creates these tiles in the United States, so customers can trust the manufacturing quality and the materials in use. Each tile carries a 5-year limited manufacturer warranty.

Will Polypropylene Garage Floor Tiles Last?

These Diamond tile products have incredible durability, ensuring a long lasting layout that will create a good value over time. These polypropylene garage floor tiles are available at less than $5 per square foot (less than $4 per square foot if you catch the right sale).For those people who have some crumbles or cracks in an existing cement garage slab, laying these tiles over the top is a cheap alternative to ripping out the old concrete and starting with a new slab.

With the labor costs included to create a new concrete garage floor, people can expect to pay at least $10 per square foot for other products. This would include tearing out the old concrete and pouring a new slab.

As long as the old slab doesn’t have significant structural damage, going over the top with these tiles will hide the cracks and provide the benefits of a new look in the flooring for a fraction of the price.

When pouring a rubbery epoxy material across the top of an existing concrete floor, with materials and labor costs, customers may pay $8 per square foot or more.

With the new tiles going over the top, the garage owner can install the tiles personally. This saves on labor costs versus pouring a new slab or an epoxy layer over the top.

Can You Use a Jack on Garage Floor Tiles?

When needing to work on a car or fix a flat tire for a vehicle parked on flooring tiles in the garage, some tiles can handle the weight and stress from using a jack and some cannot.For an especially heavy vehicle on the hard plastic tiles, the focused weight of the jack supporting the vehicle can cause damage in certain circumstances. Other times, the tiles will handle the use of the jack just fine.

While these tiles are not rated for use with a jack, the safest idea for using a jack on any garage tiles is to place a piece of scrap plywood between the tiles and the jack. This helps to spread the weight that the jack is supporting across multiple tiles, making it a safer option. (The jack may gouge the plywood.)

If using a hydraulic jack on wheels, this device should spread the weight successfully on its own.

When installing these high-quality polypropylene garage floor tiles, customers often have questions about ordering the right number of tiles, especially when mixing and matching colors. The Greatmats customer service team can review these issues with the customer and answer any other questions.